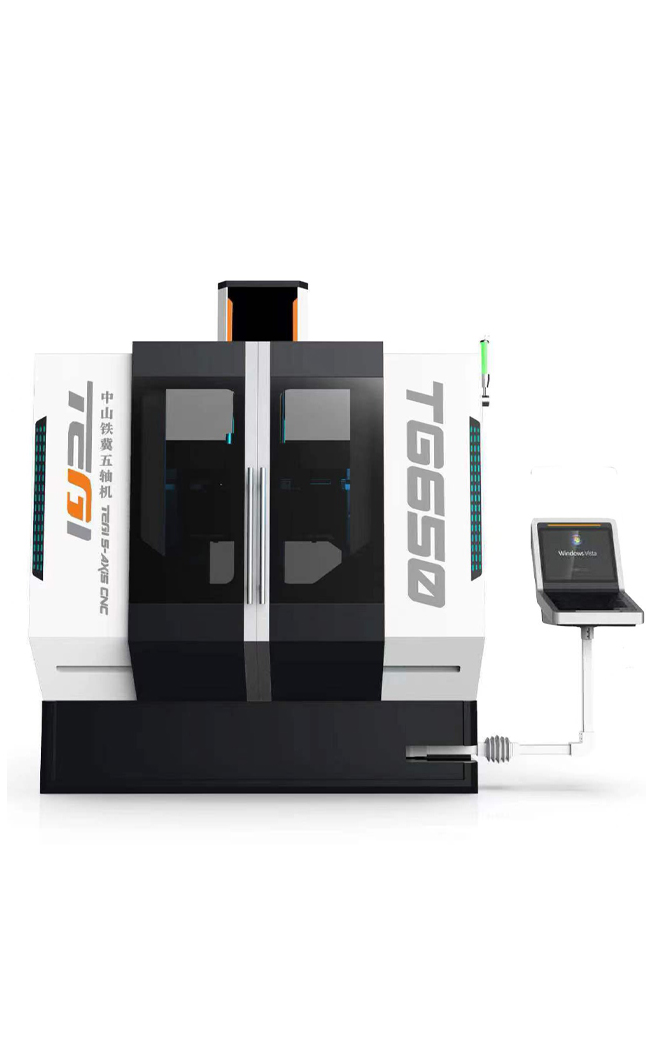

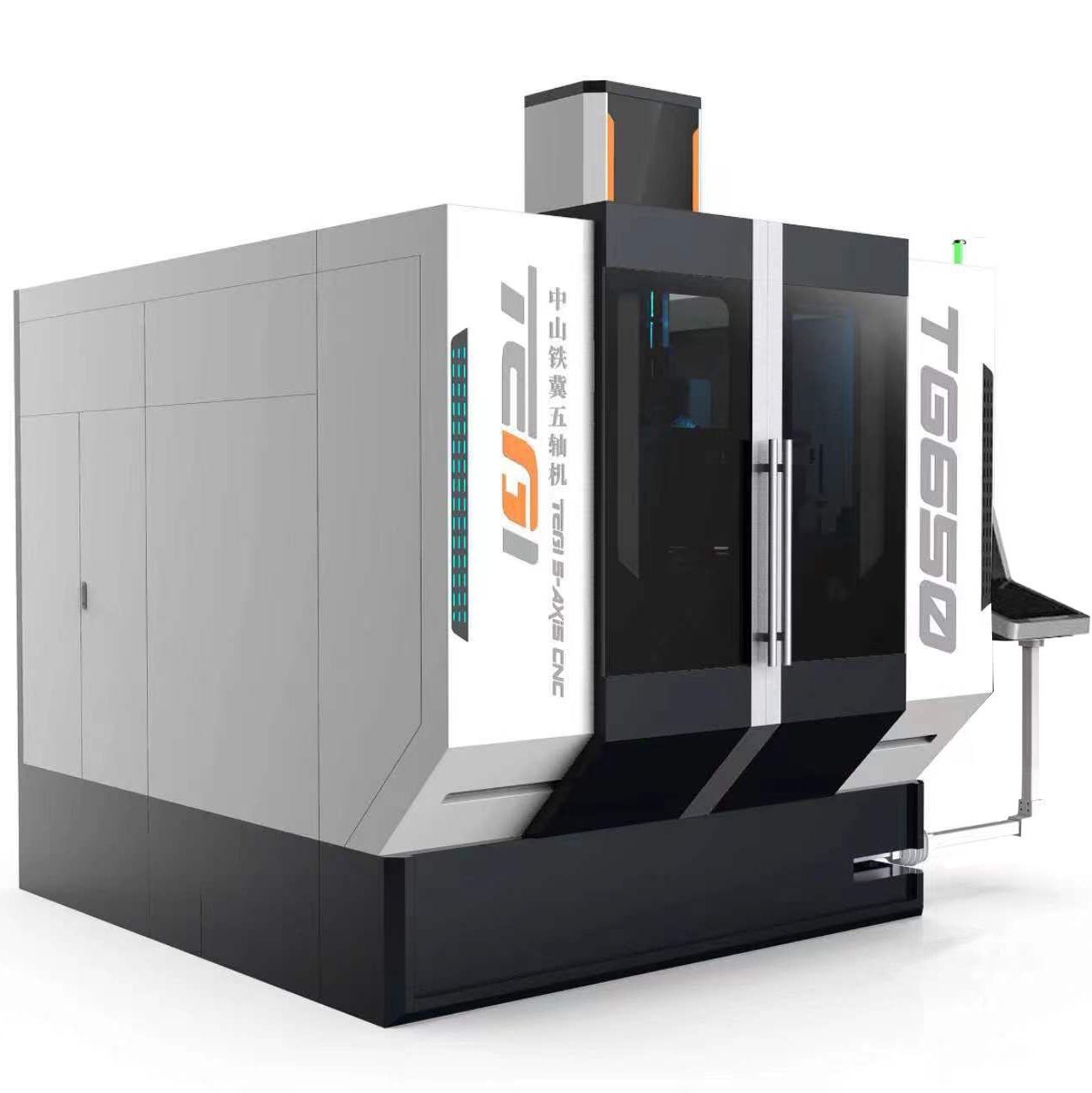

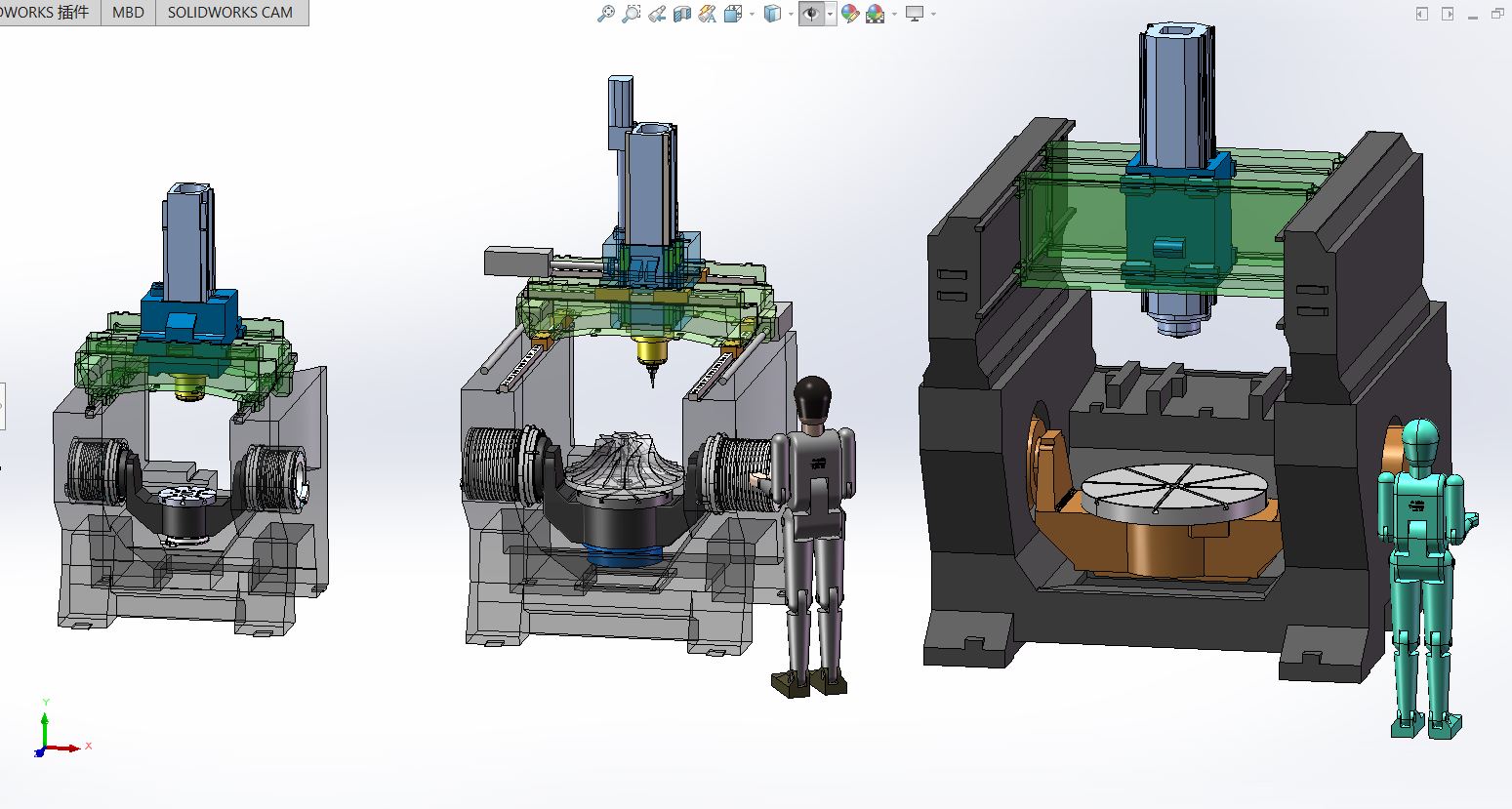

TG650

Cradle five-axis machining center

TWO. TG650 Technical Data

| Scope of work | |||

| X/Y/Z lateral path | 660/900/520 | Unit: mm | Y-axis: Front A-axis, 400; Rear A-axis, 500 |

| Processing Platform A | 100 | Unit: mm | |

| The distance from the main shaft to the worktable | Min150-Max670 | Unit: mm | |

| Diameter of the turntable | Φ650 | Unit: mm | |

| The maximum rotational space diameter of the C-axis | Φ850 | Unit: mm | |

| Table maximum load | 1000 | Unit: KG | |

| Motor - Spindle | |||

| Interface of cutting tools | HSK-A63 | ||

| Torque S1/S6 | 83/125 | Unit:NM | |

| Maximum speed | 18000 | Unit: Transfer | |

| Power | 30 | Unit:KW | |

| Spindle coolant | Available | ||

| NC rotary table | |||

| Rotation range | ± 140⁰ | ||

| Maximum speed | 30 | Unit: RPM | |

| C Rotation range | N×360⁰ | ||

| CMaximum speed | 100 | Unit: RPM | |

| An engine | DDR ×2 | 2110NM×2 | |

| CElectric motor | DDR | 964NM | |

| Tool librarys | |||

| Tool interface | HSK-A63 | ||

| Tool position | 36T | ||

| Maximum tool diameter | 80MM | ||

| Maximum tool length | 300MM | ||

| Maximum tool weight | 10KG | ||

| Machine size and weight (excluding machine parts) | |||

| Width | 2250 | Unit: mm | |

| long | 3800 | Unit: mm | |

| Height: up and down of the main shaft | 2720~3250 | Unit: mm | |

| Weight | About13 | Unit: Ton | |

| Other | |||

| Power | Three-phase380v | 150 kW | |

| Compressed air | 6-8 kg force/cm2 | ||

| Machine lubrication | T68 guide rail oil | ||

| Spindle cooling | 5 # spindle oil | ||

| Countertop cooling | Distilled water | ||

Standard configuration and main components

| No. | Number of projects | quantity | Notes |

| 1 | Siemens 840D system | 1 sleeve | |

| 2 | Fully enclosed, uncovered, body sheet metal | 1 set | |

| 3 | The working area is fully protected by stainless steel | 1 set | |

| 4 | The AC3DDR has two DDRS on the A-axis | 1 set | |

| 5 | Z-axis tool setter | 1 | |

| 6 | Z-axis tool setter HSK-A63/18000 motor - spindle | 1 | |

| 7 | HSK-A63 tool magazine | 1 | |

| 8 | Linear guide rail:X/Y/Z:55RG 1 /55RG 2/45RG 4 | 1 set | |

| 9 | Lead screw (double nut) X/Y/Z:R40-16/R40-162/R40-16 | 1 set | |

| 10 | Centralized automatic lubrication | 1 | |

| 11 | High-pressure coolant pump | 2 | |

| 12 | Fog extraction device | 1set | |

| 13 | Oil-water separation system | 1set | |

| 14 | Debris conveyor | 1set | |

| 15 | Three-color indicator lights, high-brightness LED lighting | 1set | |

| 16 | Constant temperature cooler | 1set | |

| 17 | Electrical control cabinet air conditioner | 1 | |

| 18 | XYZAC, grating ruler, circular encoder for closed-loop control | 1set | |

| 19 | Toolbox, accessory tools | 1set |

Option

| No. | Number of projects | quantity | Notes | ||

| 1 | Extended tool library | ||||

| 2 | 3D touch probe | ||||

| 3 | Laser tool measurement unit | ||||

| 4 | Security door lock | ||||

| 5 | Automatic door | ||||

| 6 | Automatic ceiling | ||||

| 7 | CNC system | Siemens 840D or HNC 848 | |||

| 8 | CNC system |

Five-axis anti-collision,DCM | |||

| 9 | Online measurement compensation, 3D toolbox | ||||

| 10 | Three-dimensional spatial compensation | ||||

| 11 | DNC | ||||

| 12 | Software service | ||||

| 13 | Back-end software | ||||

Customer preparation

| No. | Number of projects | Requirement | Notes |

| 1 | Factory building foundation | The maximum weight of the lifted item is approximately 20 tons | |

| 2 | Power cable | 16mm*3+10mm power cord (five-core) | |

| 3 | Compressed air | 1. Air source filtration accuracy: 100m \ n2. Inner diameter of the air pipe: 10mm, pressure: 6-8kgf/cm ³ Dry filtration device | |

| 4 | Equipment oil | Technical Data Page 4 | |

| 5 | Traffic conditions | 1. Select the mode of transportation based on the factory and surrounding road conditions. \ n2. Meet the net transportation dimensions of the largest component of the machine tool. \ n3. Check the lifting method according to the actual height of the factory | |

| 6 | Machine tool operation | 1. Corresponding programming and machine operation technicians \ n2. Programming computers \ n3. Cutting tools, tool rests, measurements, etc. |