CF20 Triggered Probing Head: The Breakthrough Solution for Domestic Precision Measurement

In the modern quality control system of manufacturing industries, the Coordinate Measuring Machine (CMM) is hailed as the "industrial inspection center" and the "universal measuring machine", capable of precisely measuring over 95% of geometric parameters. And as the "tentacles" of the CMM - the probe system - it is the key factor determining the measurement accuracy and efficiency.

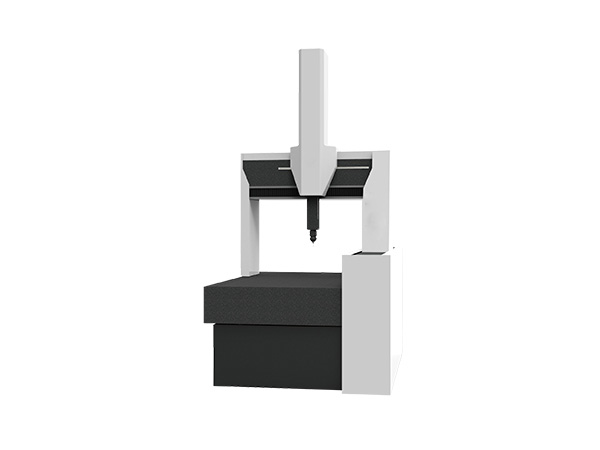

High-Accuracy Moving-Bridge Coordinate Measuring Machines

As precision manufacturing enters the “sub-micron era”, conventional gauges and dedicated fixtures can no longer satisfy the rapid, full-scale inspection of complex sculptured surfaces, 3-D hole patterns and free-form features.

Introduction to Three Coordinate Measuring Needle

The standard definition of the total length of a three coordinate measuring needle is the length from the rear mounting end face of the measuring needle to the center of the measuring ball. Effective Working Length (EWL) The effective working length is the distance from the center of the measuring ball to the interference point between the measuring rod and the measured target when measured in the normal direction of the part

What is the difference between a CMM and a profilometer?

The profiler consists of a granite flat plate, a workbench, sensors, a drive box, a display, a computer, and a printer. During measurement, different positions of the measured parts can be selected, and various measurement lengths can be set for automatic measurement

Maintenance of the Gas Path of the CMM

As compressed air plays a very important role in the normal operation of CMMs, the maintenance and repair of the air circuit is very important. The main items are as follows: 1. Check the pipes and filters before use every day, and drain the water and oil from the filter and the air compressor or air storage tank

Requirements for operators of coordinate measuring instruments

CMM operators should have basic knowledge of computers, and have a certain understanding and familiarity with optical, mechanical, and electronic knowledge. Secondly, the operator should have a professional dedication, be diligent and dedicated, and cannot be limited to simple operations