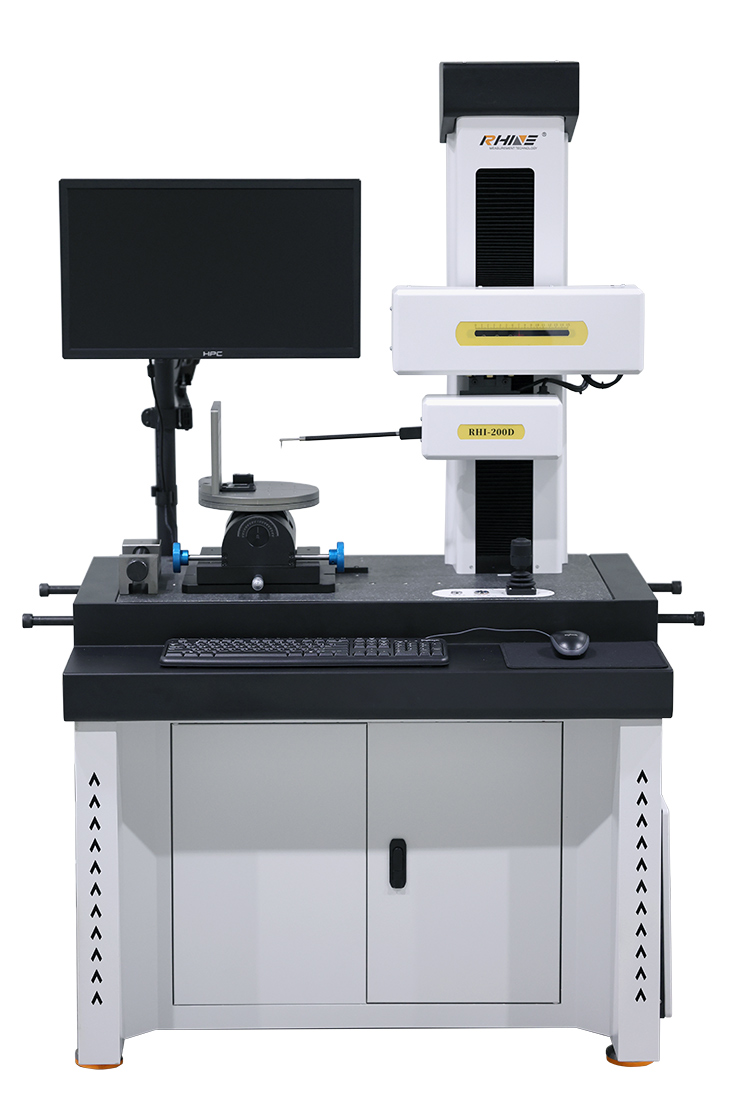

profilometer

Contour Measur ing Range:20mm

ProductAdvantages:

The roughness profilometer utilizes a contact measurement method, in which a stylus moves along the surface of the workpiece to capture its profile. One of its key advantages is the ability to directly measure surfaces that are otherwise difficult to access. The instrument can provide readings based on evaluation standards or generate detailed surface contour curves. It features high measurement speed, reliable results, and easy operation. It is capable of measuring the generatrix shapes of various precision mechanical components, including straightness, angles, convex profiles, logarithmic curves, groove depth, groove width, and more.

Optional Configuration:

A dual-stylus profilometer is available for measuring thread pitch diameters, groove diameters, inner diameters, and other related features.

ApplicationScope:

This series of instruments is widely used in industries such as machining, motors, automotive and motorcycle parts, precision hardware, precision tools, cutting tools, molds, and optical components.

It is suitable for use in research institutes, universities, metrology organizations,enterprise metrology laboratories, and production workshops. Typical measurable components include bearings, needle rollers, rollers, motor shafts, crankshafts, cylindrical pins, piston pins, pistons, valves, gears, oil pumps and nozzles, hydraulic components, pneumatic components, and textile machinery parts.

| Model | RH-2000 | RH-4000 | RH-6000 |

| Measuring Range | X-Axis Travel:140mm/200mm/300mm/400mm/600mm(Customizable) | ||

| Contour Measur ing Range:20mm | Contour Measur ing Range :40mm | Contour Measur ing Range:60mm | |

| Effective measuring stroke | Z-Axis Travel:400mm(Customizable) | ||

| Minimum Measurable Inner Diameter | 5mm | ||

| Linear Accuracy | ±(0.8+10.15H)pm | ||

| Arc | ±(1+R/12)μm | ||

| Angular | ±1' | ||

| Straightness | 0.5μm/100mm | ||

| Grating Resolution | 0.1 μm | ||

| Measuring Speed | 0.05-20mm/s | ||

| Climbing Angle | Cl imbing: 77°; Descending: 88° | ||