HMC630

1、 Functions and features:

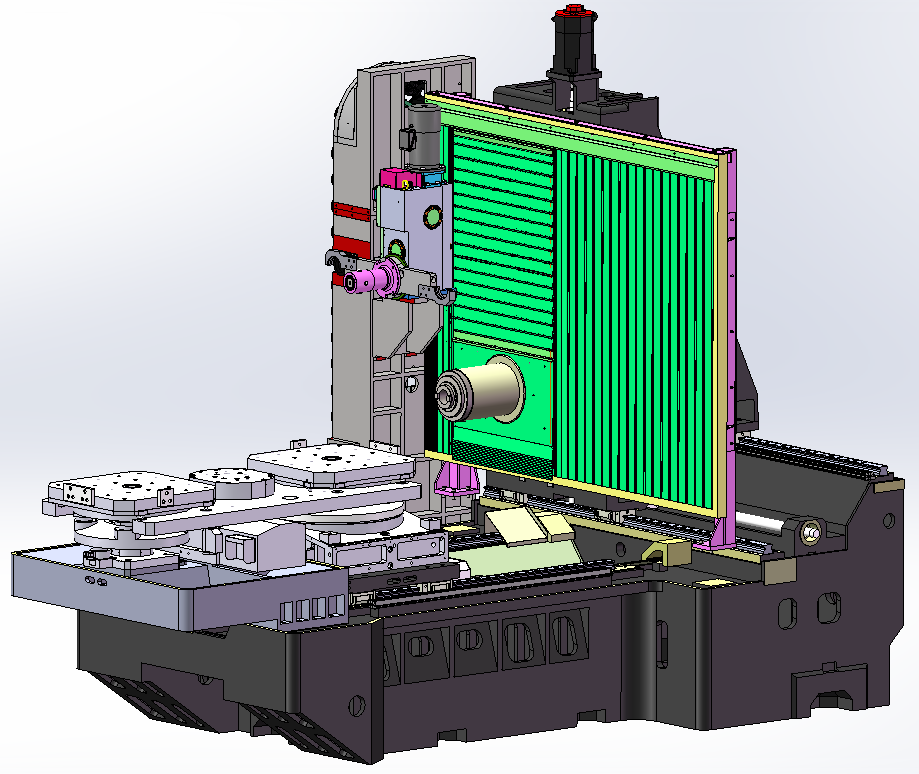

Overview of machine tool:

HMC630 machine tool is a double-station horizontal machining center, adopting three-point support T-type bed, controlled by Siemens numerical control system, with functions such as automatic exchange of worktable, automatic indexing of rotary table, stepless speed change of main shaft, water outlet of main shaft center, automatic exchange of tools, etc. It can perform linear, oblique and arc patching cutting, complete milling, boring, drilling, expanding, reaming, tapping and other processes, and realize four-axis linkage machining. It is applicable to the processing of box parts and complex parts in automobile, aerospace, metallurgy and mining, machine tool manufacturing and other industries. The machine tool is characterized by high efficiency, high precision and high rigidity. It is an efficient equipment for enterprises to improve work efficiency and flexible processing of parts. It is also an ideal equipment for processing large and medium batches of parts.

Characteristics of machine tool:

1. Large machining range, the maximum workpiece size can reach Φ one thousand × Mm;

2. Heavy duty roller linear guide rail is adopted for X, Y and Z directions, which improves the rigidity of machine tool;

3. The international famous hollow screw is used to cooperate with the oil cooler for accurate temperature control, so as to improve the stability of the machine tool accuracy;

4. The fast moving speed of the machine tool (60m/min) shortens the processing time and improves the processing efficiency;

5. The machine tool adopts three-point support machine body, and the structure is more reasonable through finite element analysis in the design process;

6. Siemens 828 system with absolute value is adopted for control, with high stability and fast speed;

7. The B axis servo motor drives the workbench to rotate through worm gear and worm gear reduction;

8. The turntable is provided with automatic indexing function, with arbitrary indexing and circular grating ruler, with high indexing accuracy;

9. The spindle is equipped with a precision electric spindle with high speed, large torque, no vibration and high machining accuracy;

10. The main shaft is equipped with an oil-air lubrication device and an oil cooling device to improve the accuracy of the main shaft;

10. The machine tool is equipped with a sealed guide rail protective cover. The X and Y protective covers are integrated wall protective covers, which enhance the protection level of the machine tool, effectively protect the guide rail and lead screw, and extend their service life;

11. Fully enclosed external protection is adopted for the machine tool to prevent splashing of cutting fluid during fast machining.

12. Operating system landing facilitates user operation and greatly protects operator safety.

13. The front part of the machine tool is provided with a large opening of the split door, which is convenient for the operator to replace the workpiece.

14. Machine tool (optional: Taiwan Deda Tool Magazine, 80 tool magazines, automatic tool change by manipulator).

15. The machine tool is equipped with an automatic lubrication system, which is controlled by an independent PLC. The oil volume is automatically distributed according to the operating distance, which greatly reduces the waste of lubricating oil and avoids the life reduction of lead screw and wire gauge caused by insufficient lubricating oil.

16. The machine tool is equipped with an automatic chip removal device in the middle of the machine tool body. The chain plate chip removal device discharges the scrap iron under the main shaft to the chain plate chip removal device at the rear of the machine tool. After being lifted by the chain plate chip removal device, the scrap iron is collected into the chip collecting car, quickly removing the residual heat on the scrap iron, and the machine tool accuracy is more stable.

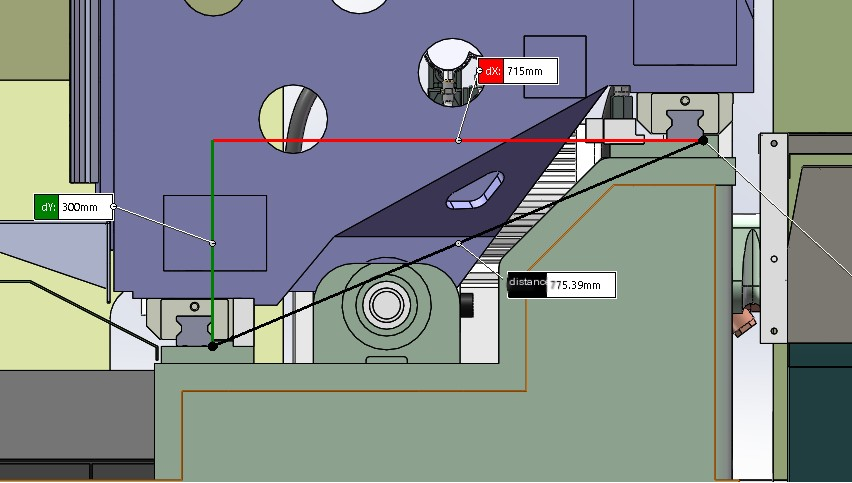

17. The guide rail behind the machine is of ladder type, low in front and high in rear, with large height difference, which can not only reduce the weight of the moving parts (columns) and improve the response speed of the machine tool, but also offset the backward overturning moment during the cutting process of the machine tool to improve the machining stability of the machine tool.

18、The machine tool is equipped with the water outlet function of the spindle center, the water outlet pressure is 7MPa, the blade can be fully cooled, the chip breaking and punching effects are available, and it is suitable for deep hole processing.

19、The machine tool is equipped with precise absolute grating ruler, with full closed-loop control and high positioning accuracy.

|

Product model |

|

unit |

|||

|

Work bench |

Table Size |

|

mm |

||

|

Number of workbenches |

|

个 |

|||

|

Maximum allowable load |

|

Kg |

|||

|

Table top form |

|

mm |

|||

|

Minimum scale unit |

|

degree |

|||

|

Maximum rotating speed of rotary table |

|

rpm |

|||

|

Scope of processing |

Maximum column travel - X-axis |

|

mm |

||

|

Maximum stroke of headstock - Y axis |

900 |

mm |

|||

|

TABLE MAX STROKE - AXIS Z |

1000 |

mm |

|||

|

Maximum rotation diameter of workpiece |

Φ 1000 |

mm |

|||

|

Axis of main shaft to Distance between worktops |

maximum |

950 |

mm |

||

|

minimum |

50 |

mm |

|||

|

Table slewing center to Distance between front end faces of main shaft |

maximum |

|

mm |

||

|

minimum |

|

mm |

|||

|

principal axis |

Tool shank form |

BBT50 |

Direct form of |

||

|

Maximum rotating speed of main shaft |

10000 |

Rpm/min |

|||

|

Maximum output torque |

200 |

N · m |

|||

|

Withstand maximum axial resistance |

65 |

KN |

|||

|

Motor power of main shaft |

|

Kw |

|||

|

Diameter of main shaft sleeve |

|

mm |

|||

|

Max. tapping diameter |

cast iron |

M30 |

mm |

||

|

carbon steel |

M24 |

||||

|

feed system |

X. Y and Z axis servo motor power |

5.2 |

Kw |

||

|

Servo motor power of axis B |

4.3 |

Kw |

|||

|

Cutting feed speed range |

1-24000 |

mm/min |

|||

|

Move fast |

X axis

|

60000 |

mm/min |

||

|

Y axis |

60000 |

||||

|

Z axis |

60000 |

||||

|

Tool magazine system |

Tool magazine form |

Tool change of manipulator |

|

||

|

Tool magazine capacity |

DISC TYPE |

hold |

|||

|

Max. tool diameter (full/adjacent empty) |

125/250 |

mm |

|||

|

Maximum tool length |

630 |

mm |

|||

|

Maximum tool weight |

30 |

Kg |

|||

|

Tool change time (tool setting) |

4.3 |

S |

|||

|

positioning accuracy |

Applicable national standards GB/T 20957 |

X axis |

0.008 |

mm |

|

|

Y axis |

0.008 |

||||

|

Z axis |

0.008 |

||||

|

Shaft B |

8 |

Arcsec (arcsec) |

|||

|

repeat positioning accuracy |

Applicable national standards GB/T 20957 |

X axis |

0.004 |

Mm |

|

|

Y axis |

0.004 |

||||

|

Z axis |

0.004 |

||||

|

Shaft B |

2 |

Arcsec |

|||

|

Numerical control system |

Model No |

Siemens SINUMERIK828D

|

|

||

|

Total number of control shafts |

5 |

Axes: |

|||

|

simultaneously controlled axes |

4 |

Axes: |

|||

|

Electrical requirements |

Power supply requirements |

KVA, 3-phase, 380V, 50HZ |

|

||

|

Air source requirements |

L/min; MPa - 0.7MPa |

|

|||

|

Overall dimensions Weight of main engine |

Floor length of machine tool |

6300 |

mm |

||

|

Floor width of machine tool |

4300 |

mm |

|||

|

Height of machine tool |

3500 |

mm |

|||

|

Weight of main engine |

20000 |

Kg |

|||